The Steel Bridge Senior Design team: Daniel Besmer, Erin Dunn, Kelsey Seibel, Lauren Hudak and Zac Fry. Not pictured: Nick Marques De Souza

Updated April 11, 2017: The CSU Steel Bridge Team is going to nationals! They placed second overall at the ASCE Rocky Mountain Conference – CSU’s best showing at the regional competition since 2003. This year’s bridge also took first place in the “economy” and “display” categories. The students will head to the national competition in Oregon, May 26-27.

Question: Can you and three friends construct a steel bridge that can withstand 2,500 pounds of stress – in under 15 minutes?

Answer: Probably not – few can. At Colorado State University, that extremely impressive party trick belongs to a group of steely-eyed civil engineering students who make up CSU’s American Society of Civil Engineers Steel Bridge Team. Six of those students will present their work during the E-Days Senior Design Showcase, April 14.

The Steel Bridge Team’s mission is to design a one tenth-scale bridge, made of many small components, that can be constructed and deconstructed quickly. The designers must adhere to strict rules and guidelines set by organizers – the ASCE and the American Institute of Steel Construction (AISC) – to score points. They are judged on all the factors that would go into a real construction project: design, size, weight, cost, efficiency, and of course, safety.

The students’ bridge-building prowess is pitted against other teams across the U.S. during regional contests. On April 6, the CSU team will head to Salt Lake City to compete in the ASCE Rocky Mountain Conference against schools from Utah, New Mexico, Wyoming and Colorado. They’ll be joined by the Concrete Canoe Team, whose competition makes up the other half of the annual ASCE student conference.

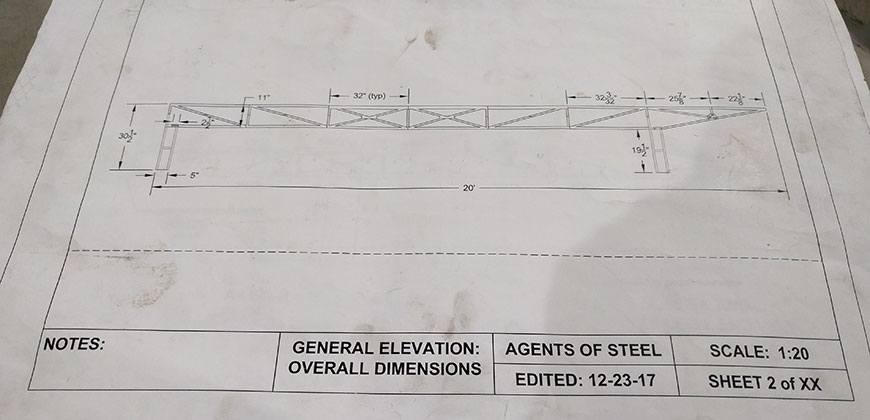

The bridge-building students have spent the better part of a year dedicating sweat and soul to their 21-foot truss bridge that rises about 30 inches from the floor. It’s painted green and gold – what else? – and it features a cantilevered end to account for “utilities” that exist on one end of a 7-foot “river” the bridge must span.

The design process

During the fall semester, the senior design group studied the thick binder of 2017 Steel Bridge Competition rules, spit-balled ideas, modeled several options, and settled on a simple truss configuration.

“We thought about the different scoring areas and what would be most important to focus on,” said senior Daniel Besmer. “We decided having a light bridge that was easy to construct would be one of our main goals.” The bridge weighs in at just 215 pounds.

The team drew up their plans, stress-tested them on the computer, and got advice from faculty advisors Chris Thornton and Hussam Mahmoud. Mahmoud, an expert in civil infrastructure, gave the students a crash course in connection design – the parts that actually hold the bridge together and are difficult or impossible to model.

A successful bridge is in “all the details,” said senior Erin Dunn. “At the beginning, you don’t realize how much goes into design. You have to learn to start big, and go into all the tiny little things, and also how to backtrack and solve problems as they arise.” That doesn’t necessarily happen in the classroom, she said.

A drawing that shows the bridge’s dimensions.

Actually building the thing

Spring semester was dedicated to fabrication and construction. All the parts were made in-house at the Engineering Research Center on the Foothills Campus. (The students pointed out that some schools pay huge sums to have their parts professionally fabricated. Not here!). The Steel Bridge Team is made up of 20 students, including underclassmen, all of whom play a key role in the finished product, and are groomed for leadership when the seniors graduate.

Leadership and communication skills have been the hallmark of team leader Lauren Hudak’s four years on Steel Bridge. From teaching underclassmen how to use fabrication equipment, to recruiting new members and fundraising, there’s a lot more to it than just the bridge.

“Teamwork has been a big part of this whole experience,” Hudak said.

Senior Zac Fry, who’s spent two years on team, said this year’s bridge is a big leap forward, not only in the bridge itself, but also in the team and how it’s run. Win or lose, “I’m really proud of all of it,” he said.

And all that theory the students learned in their freshmen and sophomore years? They get to use it to make their bridge. Those shear and moment diagrams – the calculations that show the points where a load will have the most effect? Those CAD drawings? They’d better have every detail right, if that bridge is going to withstand the infamous ASCE loading test on competition day.

“Oh, I’m attached emotionally,” Hudak said.

And the best part about studying structural engineering, for Hudak?

“I’m amazed at how many people use a bridge every day, and how much of an influence I can have as an introverted engineer hiding in an office.”