The biomedical engineering laparoscope senior design team: Michelle Fylak, Ben Melia, Matt Carter and Natalie Lusk.

If you needed surgery for a health issue, and knew there was a safer, lower-cost alternative to open-cavity surgery, would you do it? Minimally invasive surgery is this alternative, and it’s exactly what it sounds like: procedures are performed through tiny incisions instead of one large opening. Because of the small size of the incisions, recovery times are quicker and there is less of an opportunity for your body to be open to germs.

While many types of surgeries are still performed via traditional methods, companies like Applied Medical are busy creating the technologies necessary to make minimally invasive surgery more accessible to surgeons and patients alike. A Senior Design team in the School of Biomedical Engineering, sponsored by Applied Medical, is designing one of the tools needed for successful minimally invasive surgery: a laparoscope.

Improving functionality for training

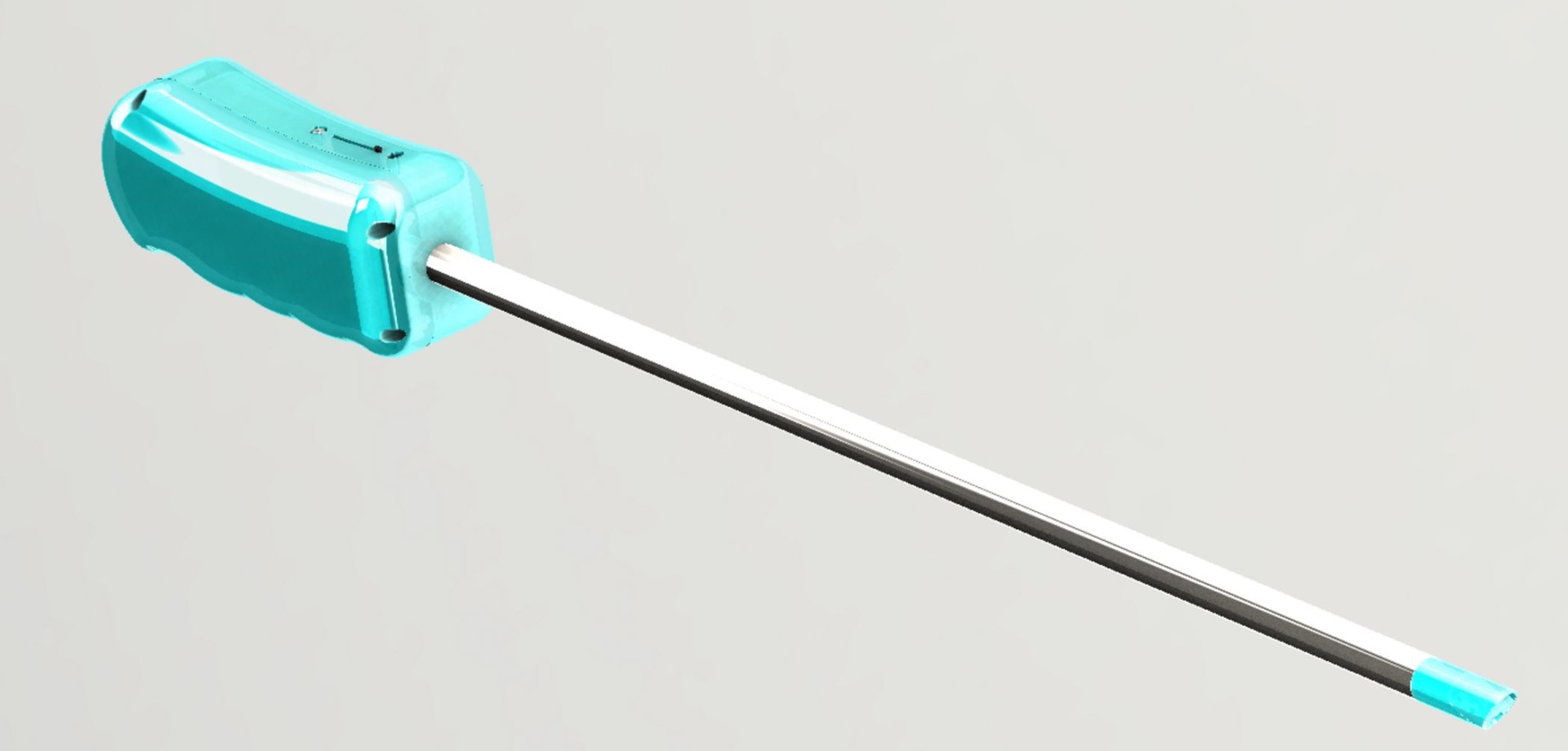

This laparoscope is for training purposes, so surgeons can practice performing a surgery and adapt to the functionality of the tool prior to having to use it on the operating table. For the students, designing a training laparoscope means more freedom with materials, as the final product will only be used in training settings, and therefore doesn’t have to go through rigorous FDA clearance and adhere to strict sterilizing standards. It’s also digital; there is an image sensor inside the device that captures imagery inside an incision during surgery, and displays that image on a monitor. Because the incisions are so small, the laparoscope is necessary to ensure visibility.

A 3D rendering of the laparoscope design, drawn in CAD design software, Solidworks.

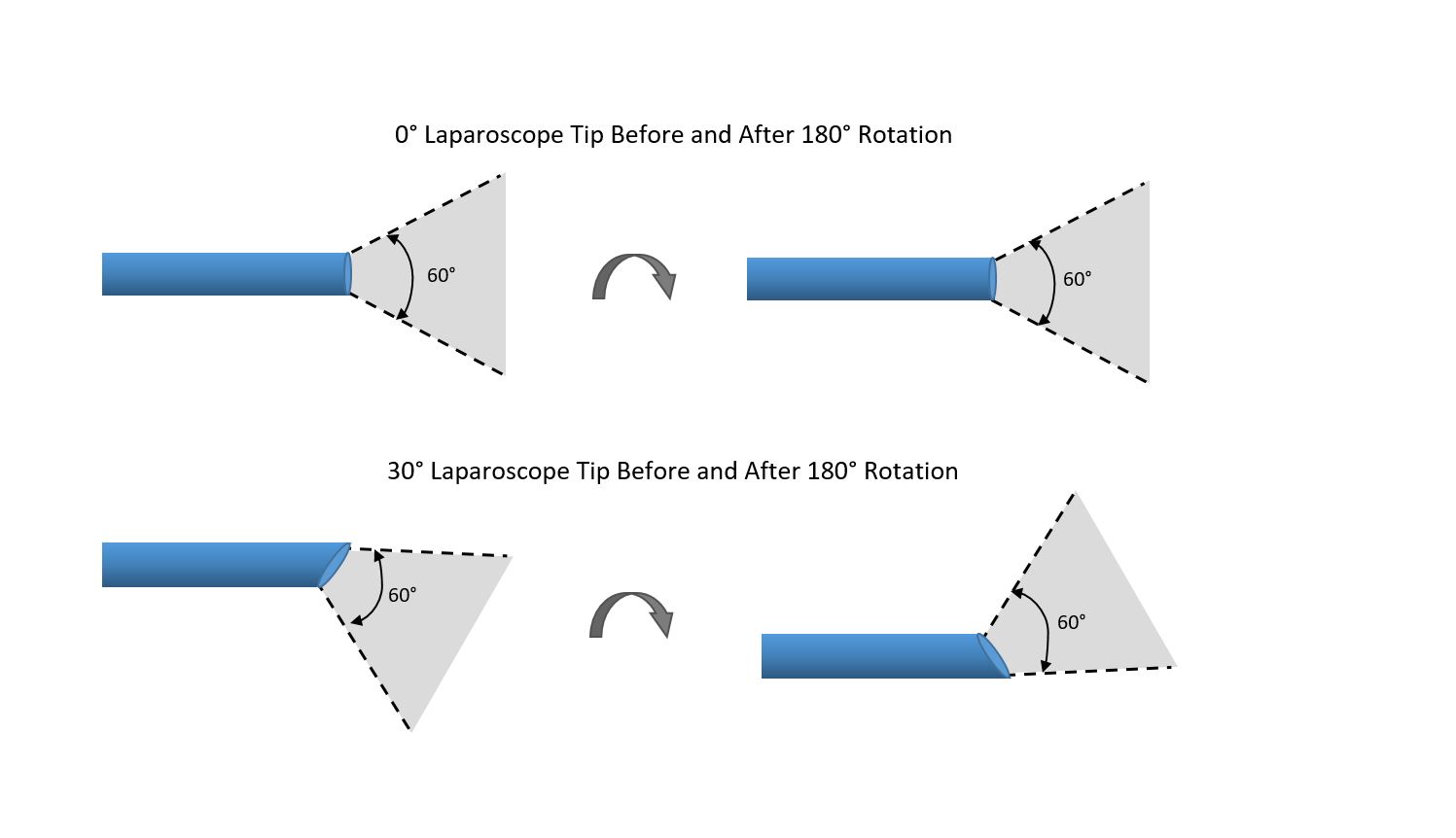

“What is especially unique about the training laparoscope is that it has a 30-degree tilt that provides a larger field of view and improved visibility,” said Matt Carter, senior biomedical engineering and electrical engineering student.

The 30-degree tilt functionality was one of the project criteria provided to the students by Applied Medical, along with the need for it to be 10mm in diameter, USB compatible, and have proper LED illumination to light up the surgical area. For the students, the criteria have provided a lot of freedom.

“They gave us a budget and a project description and said, ‘go.’ There were no step-by-step instructions, so it’s been a good experience in self managing and coming up with ideas on our own,” said Natalie Lusk, senior biomedical engineering and mechanical engineering student.

With the addition of a 30-degree tilt, laparoscope users have improved visibility, with less manipulation of the tool.

Challenges and takeaways

Each student has had the opportunity to explore a different area of the project, and each opportunity presented new challenges. For instance, despite Lusk’s two years of industry experience and design engineering, she had never come up with an idea from scratch.

“One of the biggest things I’ve learned is if your original idea doesn’t work, it doesn’t mean give up, it means keep refining and building on it until you have something that works well,” she said.

The design process proved to be a challenge for Michelle Fylak, as well, who has experience in manufacturing. For someone who likes to explore all possible solutions to a problem, the abridged senior design timeline presented an obstacle.

“In my mind, I wanted to explore all the options, but that didn’t work because our timeline is a lot shorter, so it was hard for me to fit the whole process in,” she said.

For Carter, the primary challenge was being the only electrical engineering student in the group. He was tasked with selecting and designing the optics and electronics for the laparoscope, and his initial approach didn’t work out as well as he had planned.

“Initially I had set out to design the optical array by myself on paper, which turned out to be nearly impossible. Once we recruited the help of a professional optical engineer, I realized there was software we could use that made the design process much more accessible,” he said.

Ben Melia was responsible for prototype manufacturing some of the mechanical components, which he did via 3D printing at the Idea-2-Product lab, which presented its own challenges.

“It’s been difficult to get a lot of the tiny parts manufactured. We need accuracy to a tenth of a millimeter, and only one of I2P’s printers is that accurate,” he said.

The team will present their first prototype of the laparoscope at the E-Days Senior Design Showcase, April 14. In the future, the hope is that other Senior Design groups will carry on the project, and refine function and design of the instrument.